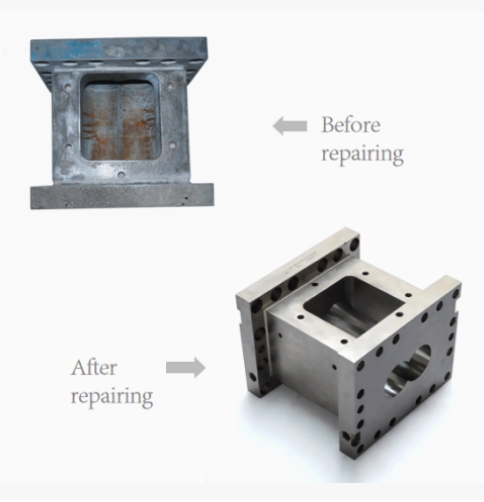

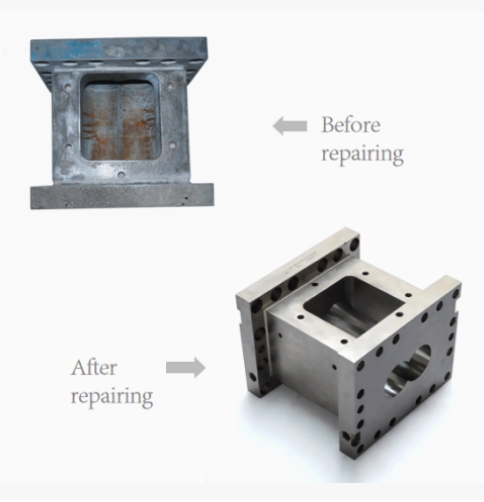

Extrusion technology is integral to numerous industries, from plastics to food processing, and ensuring the smooth operation of extruders is paramount. Here, we delve into three essential services that optimize extruder performance: Pro-Scan Screw Wear Inspection Service, Screw combination optimization service, and Twin Screw Extruder Barrel Repairing. PRO-SCAN Screw Wear Inspection Service: Predictive Maintenance for Optimal Performance The Pro-Scan Screw Wear Inspection Service employs cutting-edge technology to assess the condition of Extruder Screw Elements . Through advanced scanning techniques, this service can detect wear patterns, cracks, and other defects that may compromise extrusion efficiency. By identifying potential issues early on, manufacturers can schedule proactive maintenance to prevent costly downtime and ensure consistent product quality. Screw Combination Optimization Service: Tailoring Screw Configurations for Maximum Efficiency The Screw Combination Optimization Service offers customized solutions to enhance extruder performance. By analyzing material properties, processing requirements, and production goals, experts can recommend optimal screw element configurations to maximize throughput, minimize energy consumption, and improve product quality. Whether it's adjusting flight depth, increasing mixing zones, or incorporating barrier designs, this service helps manufacturers fine-tune their extrusion processes for optimal results. Twin Screw Extruder Barrel repairing: Extending the Lifespan of Critical Components Twin Screw Extruder barrels are subjected to extreme temperatures, pressures, and mechanical stresses during operation, leading to wear and damage over time. The Twin Screw Extruder Barrel Repairing service provides comprehensive maintenance and repair solutions to restore barrels to peak condition. From re-lining worn-out barrels to repairing damaged threads and surfaces, this service ensures the longevity and reliability of critical extrusion components.

In conclusion, professional services play a vital role in optimizing extruder performance, prolonging Equipment lifespan, and enhancing product quality. Whether it's leveraging predictive maintenance techniques to detect wear early, optimizing screw configurations for efficiency, or repairing worn-out barrels to extend their lifespan, these services offer invaluable support to manufacturers in various industries. As demand for high-quality extruded products continues to grow, investing in professional extruder services becomes increasingly crucial for staying competitive and achieving operational excellence.